Not All Magnetic Bearings Are Created Equal

Less Complexity, Reduced Maintenance

Technology choices within a chiller directly affect customer satisfaction and efficiency.

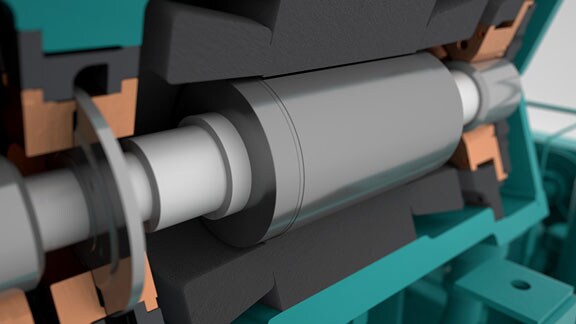

Oil-free operation within a chiller compressor generally comes down to two options: magnetic bearings or refrigerant lubricated ceramic ball bearings.

Chiller Compressor Bearing Options

When designing and selecting a chiller, technology choices like compressor bearings can have a huge impact on chiller operations.

Both magnetic bearings and refrigerant lubricated ceramic ball bearings provide oil-free chiller operation, but the two technologies are quite different. The value of magnetic bearings goes far beyond just lubrication-free or oil-free operation.

Benefits of Magnetic Bearings

Refrigerant lubricated ceramic ball bearing technology is more complex when applied in a chiller system. The simplified design of magnetic bearings, such as those in the YORK® YZ and YMC² Chillers, offers oil-free operation and many added benefits, including:

Non-contact design which improves reliability – magnetic bearings are designed to last 25 plus years

Widest operation envelope – YORK® centrifugal compressor design combined with active magnetic bearing technology means the chiller can operate any speed necessary to meet a wide range of conditions

Fewer components, such as pumps, valves, vents and filters, reduce maintenance demands

Elimination of oil reduces the chiller's environmental impact

Complex alternatives, such as refrigerant lubricated ceramic ball bearings, may provide oil-free operation, but otherwise fall short on benefits.

Technology choices within a chiller directly affect customer satisfaction and efficiency.

Oil-free operation within a chiller compressor generally comes down to two options: magnetic bearings or refrigerant lubricated ceramic ball bearings.

Chiller Compressor Bearing Options

When designing and selecting a chiller, technology choices like compressor bearings can have a huge impact on chiller operations.

Both magnetic bearings and refrigerant lubricated ceramic ball bearings provide oil-free chiller operation, but the two technologies are quite different. The value of magnetic bearings goes far beyond just lubrication-free or oil-free operation.

Benefits of Magnetic Bearings

Refrigerant lubricated ceramic ball bearing technology is more complex when applied in a chiller system. The simplified design of magnetic bearings, such as those in the YORK® YZ and YMC² Chillers, offers oil-free operation and many added benefits, including:

Non-contact design which improves reliability – magnetic bearings are designed to last 25 plus years

Widest operation envelope – YORK® centrifugal compressor design combined with active magnetic bearing technology means the chiller can operate any speed necessary to meet a wide range of conditions

Fewer components, such as pumps, valves, vents and filters, reduce maintenance demands

Elimination of oil reduces the chiller's environmental impact

Complex alternatives, such as refrigerant lubricated ceramic ball bearings, may provide oil-free operation, but otherwise fall short on benefits.