- YORK®

- Commercial Equipment

- Chilled Water Systems

- Water cooled Chillers

- YST Steam Turbine Centrifugal Chiller

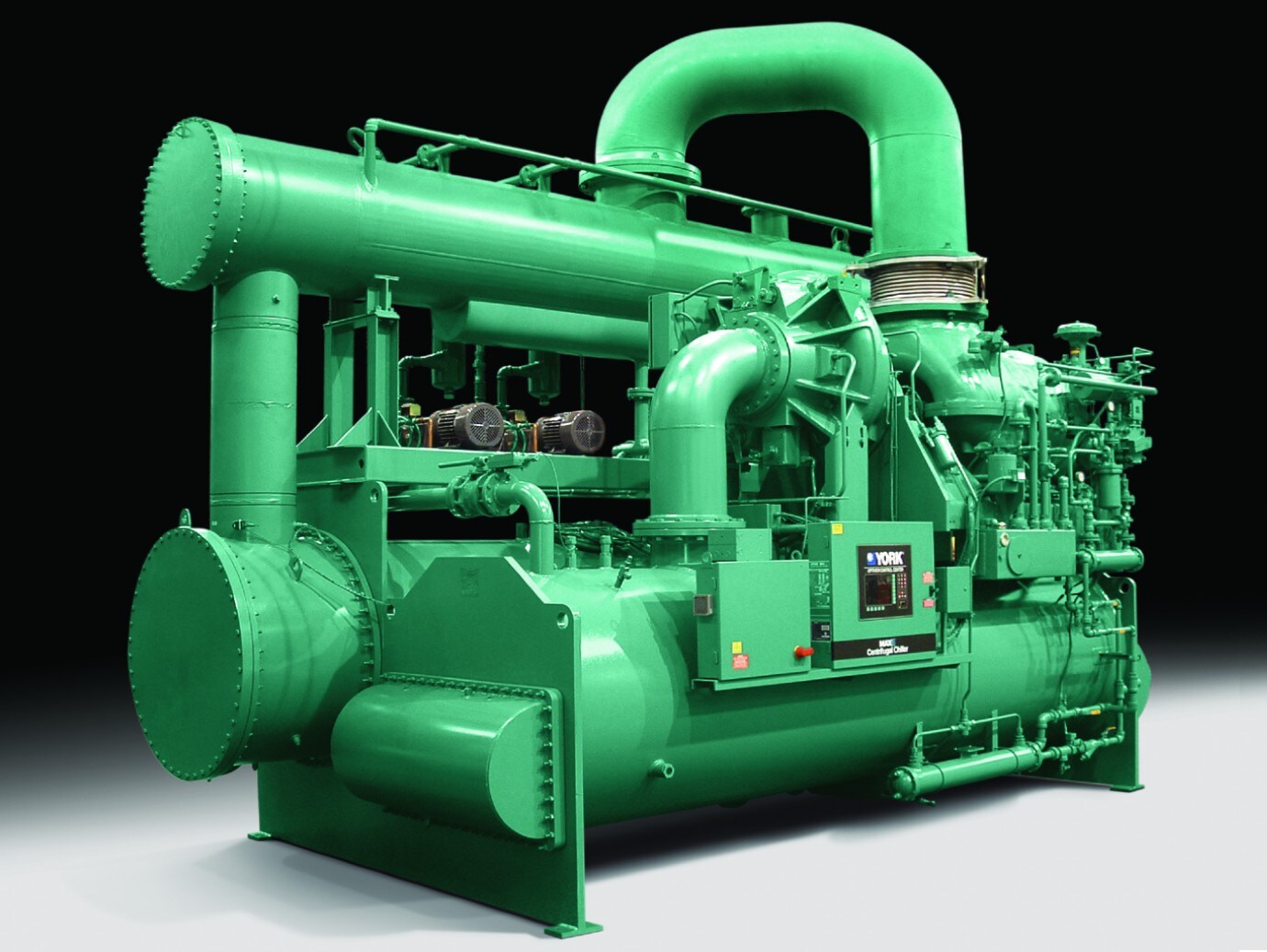

YST Steam Turbine Centrifugal Chiller

700-2800 TR (2460-9850 kW)

Greater efficiency and reduced emissions make the YORK® YST Steam Chiller the green solution for large combined-heating-and-power (CHP) plants.

- Wide range of leaving and entering-chilled-water temperatures, fluid flows and steam conditions

- Variable-speed drive for class-leading, off-design performance

- OptiView™ Control Center for easy operation and optimum performance

Designed to Use Your CHP Plant's Full Potential

The perfect choice for CHP plants, our YORK® YST Steam Chiller ensures that CHP efficiency is maintained year-round, which means less carbon dioxide and other emissions are exhausted into the atmosphere. It's a truly CHP cooling solution that's economically and environmentally friendly.

Benefits

PERFORMANCE

Variable-speed drive offers seamless performance, allowing the chiller to operate at the highest efficiency.

EASIER OPERATION

The OptiView™ Control Center ensures optimum performance, and its graphical panel makes operation easy and intuitive.

FLEXIBILITY

The YST has a wide range of temperatures, fluid flows and steam conditions, and its compact, modular configuration allows customization.

PEACE OF MIND

Low-maintenance, highly reliable and long service life. You can always count on our global service organization to maximize your savings.

Features

- Variable-speed driver delivers superior performance at both design and off-design conditions for higher efficiency

- Modular configuration provides maximum flexibility, customization and compact footprint

- Low noise as chiller operates at significantly reduced sound levels compared to many electric chillers

- Application flexibility of the chiller handles a wide range of leaving- and entering-chilled-water temperatures, fluid flows and steam conditions

- Mix-and-match components ensure proper fit and prompt delivery

- OptiView™ Control Center displays steam conditions and automatically determines efficiencies by presenting more data in the friendliest possible way

Steam Turbine

In the real world, chillers operate nearly 99% of the time at off-design conditions. How a chiller operates at off-design determines actual energy costs. The YST chiller is designed to deliver superior performance at both design and off-design conditions. It's engineered to take advantage of the steam turbine’s inherent variable-speed capability to seamlessly optimize chiller speed and to handle low entering-condenser-water temperatures, allowing the chiller to operate at the highest efficiency.

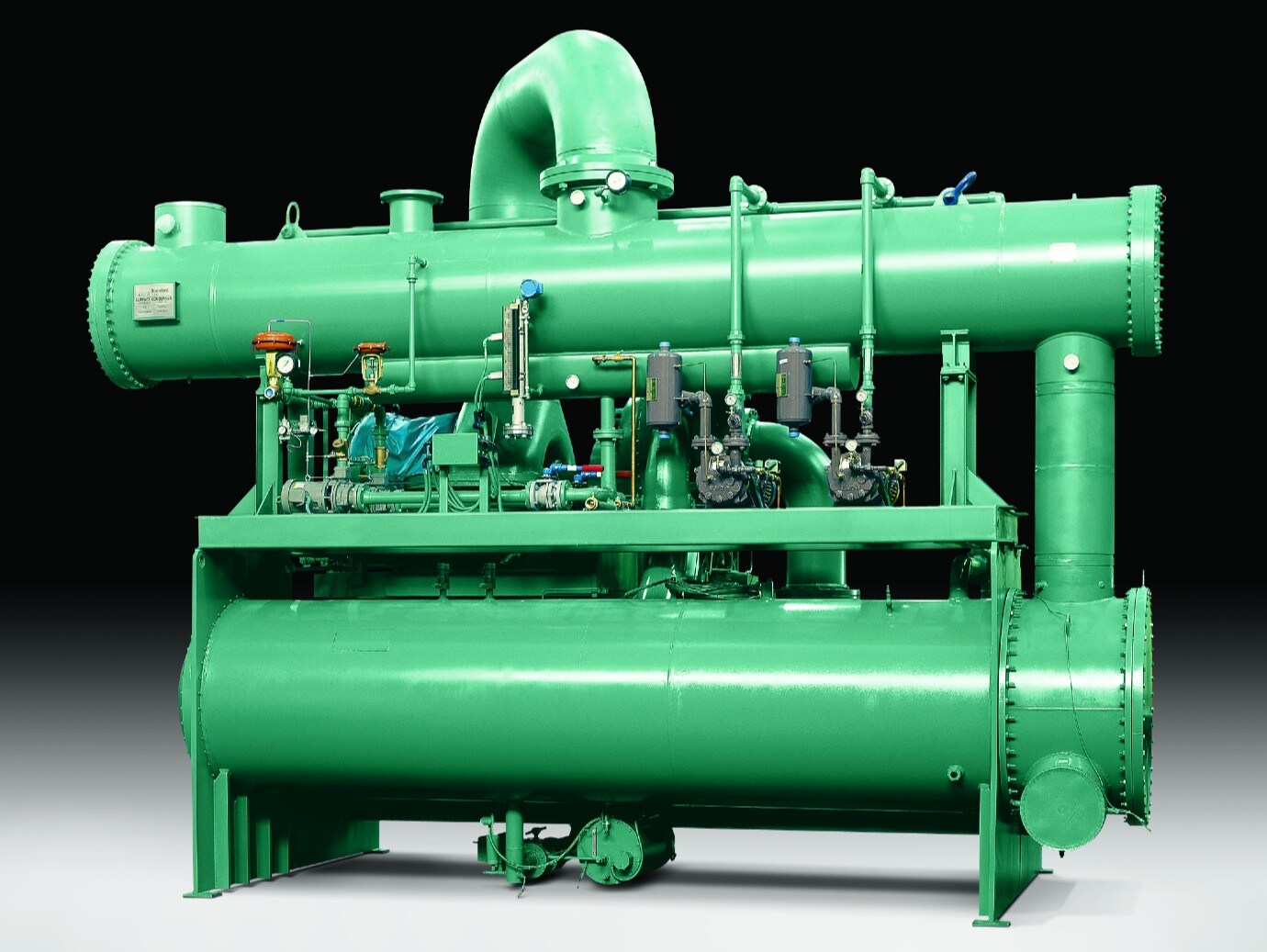

Modular Configuration

The components of the YST chiller are predesigned to ensure proper fit and prompt delivery. All steam components required to efficiently manage the turbine-exhaust steam are supplied within the chiller package. The YST chiller places the steam condenser on top of the chiller, so the footprint is smaller than competitive steam-turbine-drive chillers and much the same as a compact electrical chiller.

Optiview™ Control Center

At the heart of the system is the OptiView™ Control Center. It offers an industry first – a fully automatic start. Its powerful microprocessor and graphical user interface present more data in the most intuitive way. The large, active-matrix, color screen shows data in relation to illustrations of the key chiller components. In operation, proven OptiView control logic continually monitors all chiller and steam conditions and automatically determines the most efficient way to run the chiller.

Technical Resources

Document Name

Description

Language

Resource Type

Back

Next

Related Products

- Innovative YORK® two-step evaporator and absorber design enhances absorption of the refrigerant into the concentrated solution, reducing overall pressure and risks of crystallization.

- Lower pressure steam into the generator can be used to drive the absorption cycle for higher system efficiency.

- Solution plate heat exchanger optimizes efficiency by enabling effective heat transfer between the diluted and the concentrated lithium-bromide solutions.

- Two-step evaporator and absorber design enhances absorption of the refrigerant into the concentrated solution, reducing overall pressure.

- Parallel flow cycle enables lower lithium bromide solution concentrations, reducing crystallization risk and the potential for corrosion.

- Variable-frequency drive (VFD) solution pump provides superior part-load performance to reduce steam consumption versus constant-speed pumps.

SMART

READY

- Designed with sustainability in mind, the re-engineered YK chiller has been optimized specially for use with ultra-low GWP refrigerant R-1234ze

- ISASecure® certified YORK® Chiller Access Manager provides secure access to chiller controls to help mitigate the risk of unauthorized access and security breaches

- State-of-the-art OptiView™ Control Panel optimizes chiller performance by precisely controlling the leaving chilled liquid temperature and motor current

- Uses zero-ODP, R-134a or R-513A refrigerant

- Industrial, reliable, long-lasting proven design

- Custom multi-stage chiller with flexible options of steam turbine or electric motor with variable speed drive