Advanced Steam Turbine Centrifugal Chiller Technology

A Growing Trend in Older Technology

Steam-turbine-driven centrifugal chillers are becoming a popular choice thanks to stable, low-cost natural gas. As natural gas prices continue to drop, this almost century-old technology is becoming more attractive in large combined heat and power (CHP) applications.

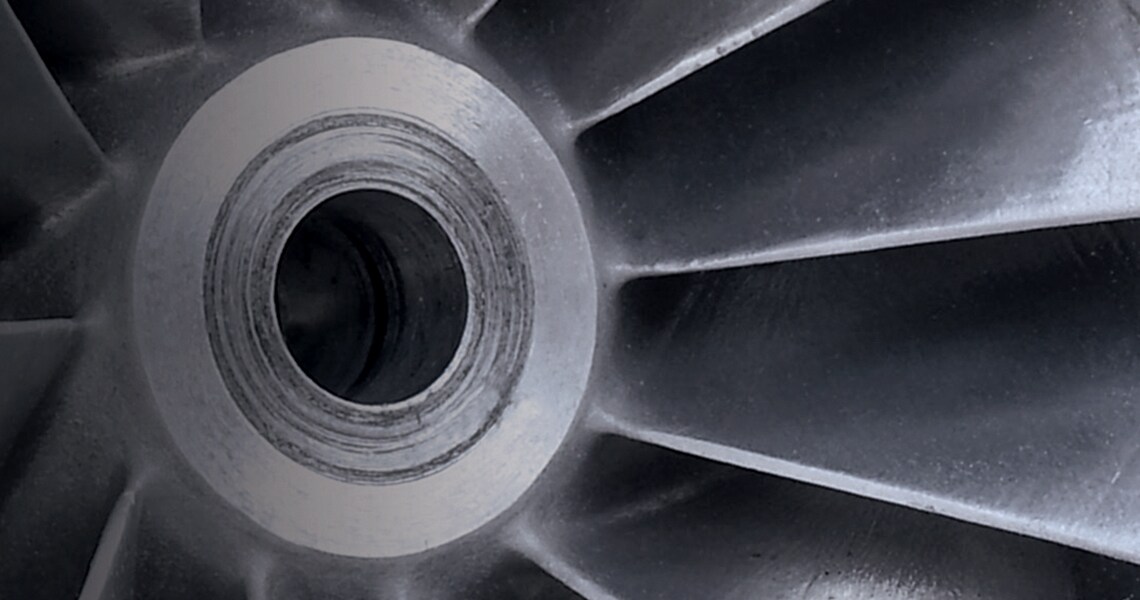

Steam-turbine-driven chillers are centrifugal vapor-compression chillers. While similar to their electric counterpart, they differ by using rotational power to drive the chiller rather than an electricity-driven motor.

In this article published in Process Cooling, YORK® experts explain how steam-turbine-driven chillers perform in real-world conditions – particularly how they provide relatively low-maintenance, highly reliable operation and a long service life:

“Chemical, pharmaceutical, paper and textile industries can benefit from steam-turbine-drive cooling as well as CHP plants. These applications also benefit from the reduced annual operational costs and the ability to achieve greenhouse gas reduction targets. Moreover, some utility companies offer rebates and incentives for deploying steam turbine chillers.”

The article also shares comparisons between electric and steam chillers, how they compare in capacity and what the economic payback is between each.

Steam-Turbine-Driven Benefits

- Low maintenance

- Reliable operation

- Reduced greenhouse gases

- More affordable with natural gas prices